【Answered】Do Lithium Batteries Leak? How to Prevent?

Lithium batteries have seen extensive use across many applications thanks to their high energy density and low rate of self-discharge. However, one potential downside is the possibility of leakage from lithium batteries.

This article will explore the issue of battery leakage in more detail and provide recommendations on how to minimize the risk of leaks occurring.

How Lithium-Ion Batteries Work: A Look at the Chemistry

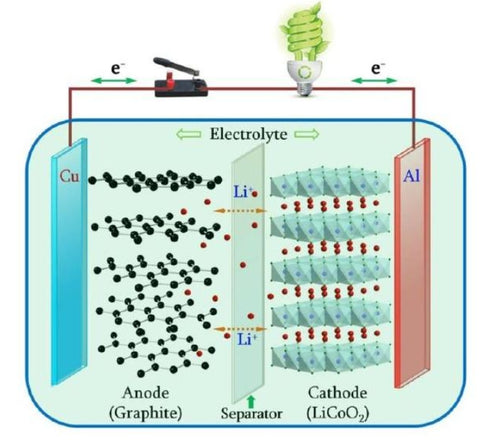

Understanding the chemical processes that occur inside lithium-ion batteries is crucial for appreciating both their advantages and limitations. At its core, a lithium-ion battery utilizes reversible redox reactions involving the shuttling of lithium ions between two electrodes - a cathode and an anode - to produce electricity.

This shuttling enables the battery to repeatedly store and release power through insertion and removal of lithium ions. The cathode typically uses lithium cobalt oxide or lithium iron phosphate, while graphite is commonly used as the anode. When charging, lithium ions are extracted from the cathode material and intercalated into the anode. During discharge, the reverse process takes place as the lithium ions diffuse back to the cathode.

Do Lithium Batteries Leak?

While lithium-ion batteries are generally safe when handled properly, there remains a small risk of leakage as with any energy storage system. To mitigate this risk, it is important to ensure the battery voltage matches the rated input of the device and that the equipment can accommodate the lithium battery specifications.

Lithium-ion chemistries provide considerable energy density for long-lasting power on the go. Unlike alkaline batteries, they do not vent gases even under conditions of elevated pressure or moisture exposure. Their capability to hold a charge when not in active use has made lithium batteries very popular for portable electronics.

Several best practices can help minimize any leakage potential. Batteries should be stored in a cool, dry place with a moderate state of charge between 50-70%. Quality manufacturing and avoiding physical damage to the casing is also important. Using matched chargers designed for lithium-ion and disposing of damaged or swollen cells properly further reduces risks.

What Causes Lithium-ion Batteries to Leak?

Here are some possible causes of lithium-ion battery leaks:

Damage to the battery casing

Lithium-ion batteries have a rigid casing made of aluminum or other material that contains the electrodes, electrolyte, and other internal components. physical damage from drops, excessive pressure, or other impacts can cause fractures or cracks in the casing that allow liquids to escape.

Electrolyte degradation over time

The liquid electrolyte inside batteries can slowly break down over hundreds of charge/discharge cycles. As it degrades, its ability to contain the lithium ions can diminish, possibly leading to leaks. Heat and long storage periods can accelerate electrolyte degradation.

Manufacturing defects

On rare occasions, flaws introduced during battery manufacturing processes before sealing can result in cracked or improperly formed casings. Underlying defects may not cause immediate issues but could promote future leaks.

Internal short circuits

If the conductive cathode and anode materials become directly connected inside the battery through damage or contaminants, it can cause short circuits, heat generation, and volatile chemical reactions. These issues can potentially puncture the casing over time.

Improper use/abuse

Extreme overcharging, discharging to extremely low levels, exposure to high heat without proper cooling, or mechanical/electrical abuse from bending, crushing, or overloads are all risks that could accelerate battery aging and structural failure.

The main causes essentially come down to anything that compromises the integrity of the battery casing over time through physical impacts, chemical/electrolyte breakdowns, manufacturing flaws, or misuse/abuse of the battery. Proper handling and regular replacement of older batteries can help reduce leak risks.

How to Prevent Lithium Batteries from Leaking?

Here are some tips to help prevent lithium batteries from leaking:

- Use batteries designed for your device. Using batteries with incompatible voltage can stress and damage them.

- Store batteries properly. Keep them in a cool, dry place at room temperature away from heat sources.

- Avoid fully charging or depleting the battery. Keep the charge between 30-70% for long-term storage.

- Inspect batteries regularly for signs of damage or swelling. Carefully dispose of damaged batteries.

- Only use approved chargers designed for lithium-ion batteries. Unregulated chargers can cause overcharging.

- Don't leave batteries in hot locations like cars or direct sunlight where temperatures rise high.

- Don't discard batteries in trash. Take them to hazardous waste collection for safe disposal.

- For long-term storage, remove batteries from devices and store separately.

- Be gentle - avoid dropping or applying pressure to prevent cracking the casing.

- Don't attempt to modify or repair batteries. Only use chargers and replacement parts approved for that battery model.

With careful handling, proper storage between uses, regular inspections, and responsible disposal, lithium batteries can last a long time with minimal risk of leaks developing if these precautions are followed. Proper battery care is important for safety.

Exploring Common Leakage Risks in Divergent Lithium-Ion Cell Designs

Cylindrical Lithium Batteries

Manufacturing Issues:

- Faulty welding of the battery shell and cap, leaving cracks or unsealed areas

- Improperly sized or mismatched sealing components like steel balls that don't create a tight seal

- Loose or poorly attached positive electrode on the cap, introducing gaps

- Worn insulating gaskets prone to corrosion over time

Usage Issues:

- Non-OEM batteries with excessively high voltage/current stressing internal parts

- Physical impacts during normal use weakening the structure over time

- Abnormal charging methods like overcharging or high current discharge damaging protections

Pouch Lithium Batteries:

Packaging Process Issues:

- Moisture infiltration if the sealing process is ineffective

- Insufficient sealing of edges and contacts points in the aluminum-plastic packaging

Chemical Corrosion:

- Moisture reacts with electrolyte producing hydrofluoric acid which corrodes packaging

- Chemical reactions between lithium hexafluorophosphate and moisture form PF5 and HF acids

Electrochemical Corrosion:

- Ion short circuits form between aluminum packaging and anode over time

- Electronic short circuits develop within the aluminum layer

- Accidental contact between negative electrode and aluminum packaging

Usage-Induced Issues:

- Internal stresses from overcharging, over-discharging or high temperatures

- External punctures or impacts damaging the packaging integrity

- Battery swelling putting pressure on the seals

- Aging and failure of the sealing compounds around edges and contacts

How to Tell If A Lithium Battery is Leaking

Here are some ways to detect if a lithium battery is leaking:

Visual Inspection:

- Look for physical signs like swelling, bulging, cracks or holes in the battery casing.

- Check for white or colored deposits like residues or stains around the casing seals or vents.

Odors:

- Strong chemical odors, especially around exposed areas of the battery contacts, can indicate an electrolyte leak.

Testing:

- Apply water or a leak detector solution to suspicious areas. An electrolyte leak will cause bubbling or a color change reaction.

Voltage Test:

- Use a multimeter set to voltage to check contacts. No voltage could mean an internal short from a leak.

Impedance Test:

- Specialized battery test equipment can detect internal issues like rising impedance from a developing leak.

Performance Monitoring:

- Notice if battery life or capabilities deteriorate rapidly, which may precede a leak failure.

Environmental Conditions:

- Leaks more likely if battery was subjected to temperatures, impacts or stored improperly.

Safety Check:

- Watch for unusual heat generation, smoking, discoloration or other potential unsafe signs of a damaged integrity.

If evidence suggests a lithium-ion battery may be leaking its electrolyte, it should not be used or charged further due to chemical and fire hazards.

How to Handle a Leaking Lithium Battery

Here are the steps to properly handle a leaking lithium battery:

- Stop using the battery immediately if you notice any swelling, damage, heating, or liquid leaking from the battery.

- Carefully contain and isolate the battery away from combustible materials. Place the battery inside a fireproof container like a metal cookie tin or bucket filled with sand.

- Evacuate the immediate area and keep all sources of ignition well away, including sparks, open flames or heated surfaces. Lithium battery fires can ignite quickly.

- Wear protective gloves and safety goggles to handle the battery. The leaked liquid can cause skin and eye irritation.

- Place battery containers or used tissues used to soak up liquid in a sealed bag before disposal to avoid further leaks.

- Ventilate the storage area well due to possible hydrogen gas emission.

- Contact your local hazardous waste collection program for instructions on proper battery disposal. Never discard leaking batteries in household trash.

- Seek medical attention promptly if the leaked liquid contacts your skin or eyes. Provide SDS details to medical responders.

- Notify manufacturers if a systemic issue with certain battery brands is suspected.

Safety is critical when dealing with damaged lithium batteries. Always protect yourself and properly dispose of them to avoid fire risks. Never attempt to charge or use damaged batteries.

What is The Most Unlikely to Leak Lithium Battery

Among leading lithium-ion battery chemistries, lithium iron phosphate (LiFePO4 or LFP) technologies have demonstrated enhanced intrinsic resistance to leakage issues compared to alternatives like lithium-cobalt oxide or lithium-nickel-manganese-cobalt oxide. A stable phosphate cathode and inert electrolyte system contribute to reduced chemical reactivity that can otherwise initiate unwanted releases.

While much safer overall, no battery technology can be entirely faultless or immune to all failure modes. However, LFP batteries are far less prone to thermal runaway chains due to their chemistry's retarded oxidation properties. This lowered risk of uncontrolled overheating alleviates a primary driver for chemical rupture and leakage in less stable lithium-ion cells.

Additional advantages like expanded temperature operating ranges and longer cycle life expectancy further diminish leakage likelihoods. By minimizing stresses on containment mechanisms, LFP batteries can better shield enclosed electrolytes from environmental exposure over broader use profiles than many competitors.

Of course, prudent handling always remains important. But LFP technologies' inherent attributes provide a formidable foundation for enhanced protection against unwanted emissions throughout battery service life. For applications favoring utmost safety, their phosphate compositions represent a compelling option.

Does a LiFePO4 Lithium Battery Leak Toxic

No, a lithium iron phosphate (LiFePO4) battery is significantly less toxic if it leaks compared to other lithium-ion battery chemistries.

The key differences are:

LiFePO4 batteries use a lithium iron phosphate cathode material instead of the more common lithium cobalt oxide (LCO) or lithium nickel manganese cobalt oxide (NMC) chemistries.

They contain a liquid electrolyte similar to other lithium-ion batteries, but it can be made with more stable and less toxic components like LiPF6.

If the battery casing is damaged and the electrolyte leaks, it may cause minor skin or eye irritation but is not highly corrosive or toxic like electrolytes in other lithium cells.

There is no risk of heavy metal toxicity from leaked components, as LiFePO4 batteries do not contain cobalt, nickel or manganese like other lithium chemistries.

Electrolyte vapors from a LiFePO4 leak are irritating but less hazardous than those from leaked LCO or NMC type batteries.

A leaking or damaged LiFePO4 battery still needs proper handling due to fire risk, but it presents much lower acute toxicity compared to other lithium-ion battery chemistries.

So in summary, while any battery leak requires care, a LiFePO4 battery leak is significantly less toxic than most other lithium-ion types thanks to its more stable chemistry and lack of toxic heavy metals. Appropriate precautions are still advised.

Redodo: Pioneering Safe, Sustainable Lithium Solutions

As a lithium industry leader for over a decade, Redodo is globally recognized for developing top-tier yet affordably priced lithium iron phosphate (LiFePO4) battery systems. Revolutionary cell engineering has achieved over 4,000 deep-cycle charges per battery - a service lifespan exceeding 10 years under typical use.

Redodo's prismatic LiFePO4 designs outperform traditional batteries, delivering stable power in any climate. With minimal self-discharge and best-in-class thermal tolerance, these systems reliably support demanding commercial and industrial applications that traditional chemistry cannot.

Learn more reviews about Redodo.

Conclusion

While leaks can potentially occur with any battery chemistry depending on conditions, lithium iron phosphate (LiFePO4) technology significantly minimizes this risk factor thanks to inherent design advantages. When coupled with prudent use practices, LiFePO4 power solutions offer a superior balance of safety and reliability versus alternatives.

Adhering to use guidelines from qualified manufacturers allows consumers and commercial/industrial users alike to benefit from LiFePO4’s power potential with confidence in its consistency and containment. While no system warrants complacency, this chemistry’s resilience supports maximized uptime with minimal leak probability when handled according to best practices.

Redodo

Redodo

Join Redodo

Related Post

What Is the Best Marine Battery: Type, Size, and Buying Guide

How to Plan a Perfect Off-Grid RV Camping Trip: 2026 Guide

How to Charge a 24V LiFePO4 Battery? Best Practice

Redodo 12V 320Ah Mini Battery Review: 4kWh Power for Multi-Day RV Camping